Continuous sandwich panel line

Automatic plant for continuous sandwich panels production, with polyurethane (PUR-PIR), mineral wool and polystyrene.

Uncoiling Section

Double uncoiling station with automatic loading of the coils complete of automatic joining system of the sheets to work in continue without line stop.

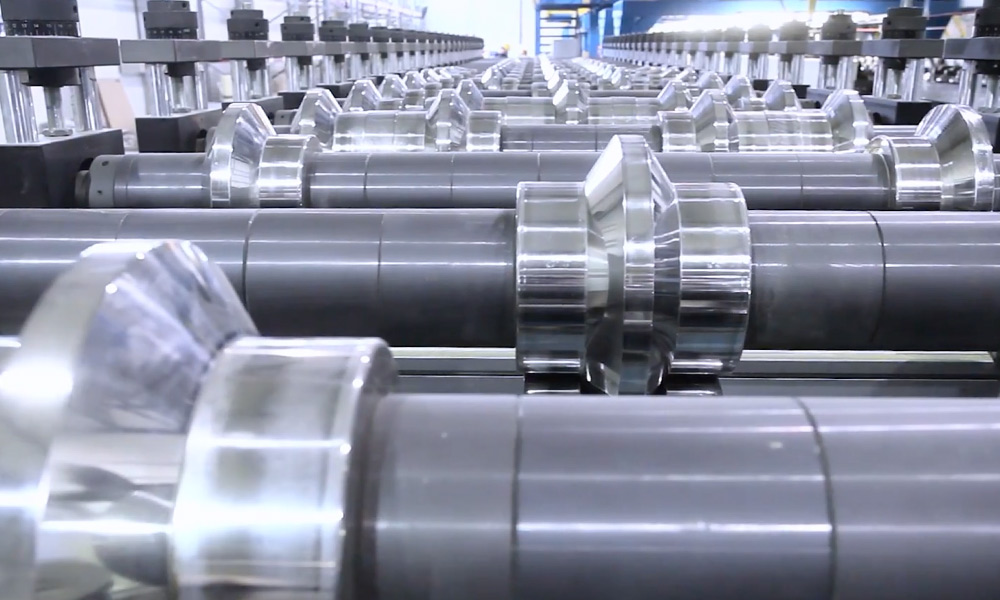

Roll Forming Section

Profiling line for the sheet with cassettes system for a quick set up of the production.

Foaming Section

Multi components machines for foam dosing and distribution.

Mineral Wool Section

Line for preparation of mineral wool and / or polystyrene to obtain strips with oriented fibers and trapezoidal strips.

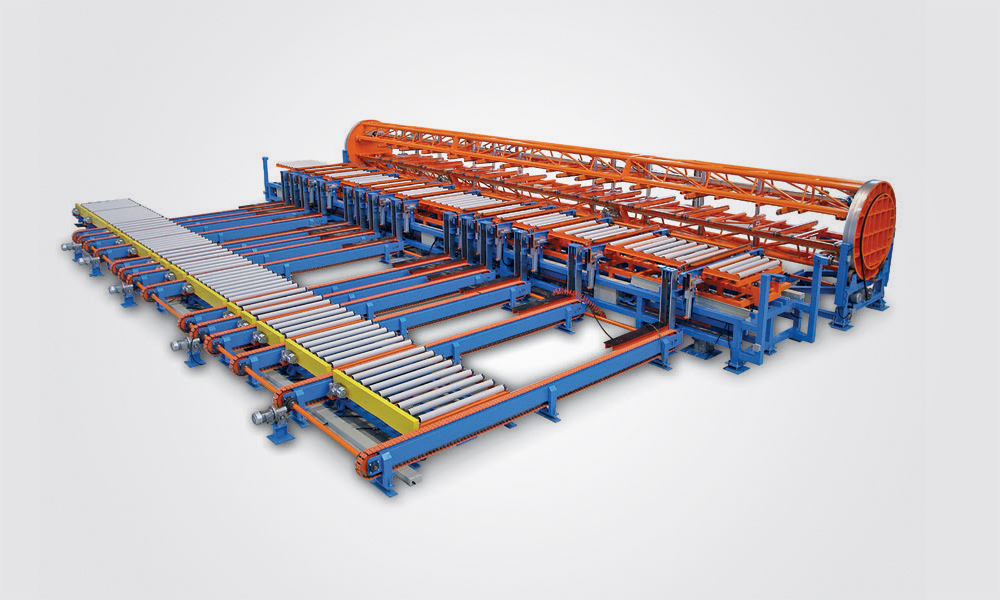

Continuous Press

Double belt conveyor with motorised side containments.

Cutting Section

"On the fly" cutting machine with single or double band saw, single or double disk.

Cooling Section

The cooling system is used for the panel curing.

Stacking Section

Tilting and stacking of the panels with sliding arms or vacuum devices.

Packing Section

Front, rear and radial stretch wrapping system with automatic feeding system of blocks or pallets under the bundle of panels.