Characteristics

The roll forming section is a set of machines designed to form the metal sheet surfaces and edges for the following kind of sandwich panels:

- wall panels with visible fixation;

- wall panels with concealed joint;

- cold store panels;

- roof panels with trapezoidal shape;

- roof panels with roof-tile shape;

- roof/wall panels with sinusoidal shape;

- insulated sectional doors/garage panels.

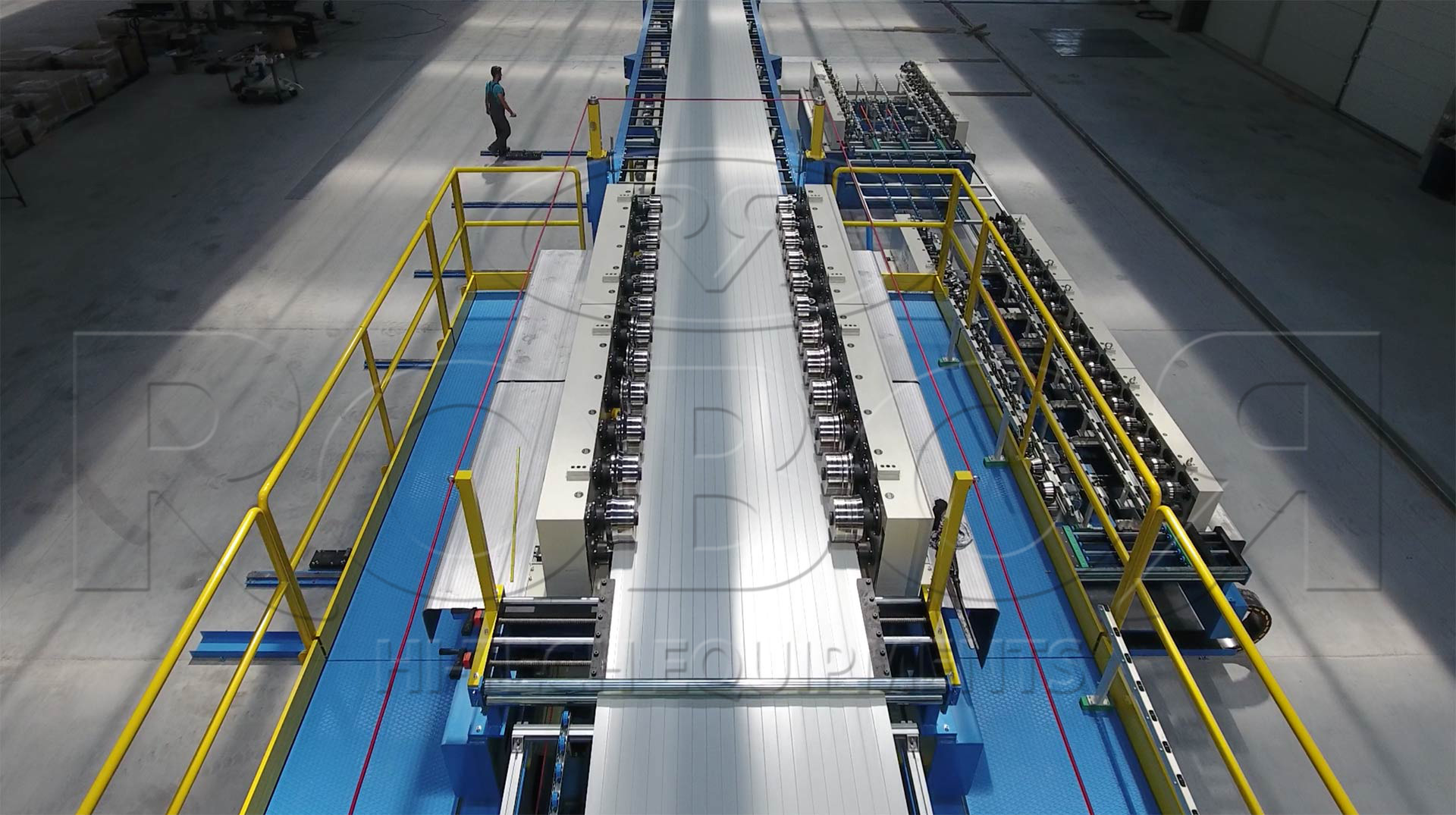

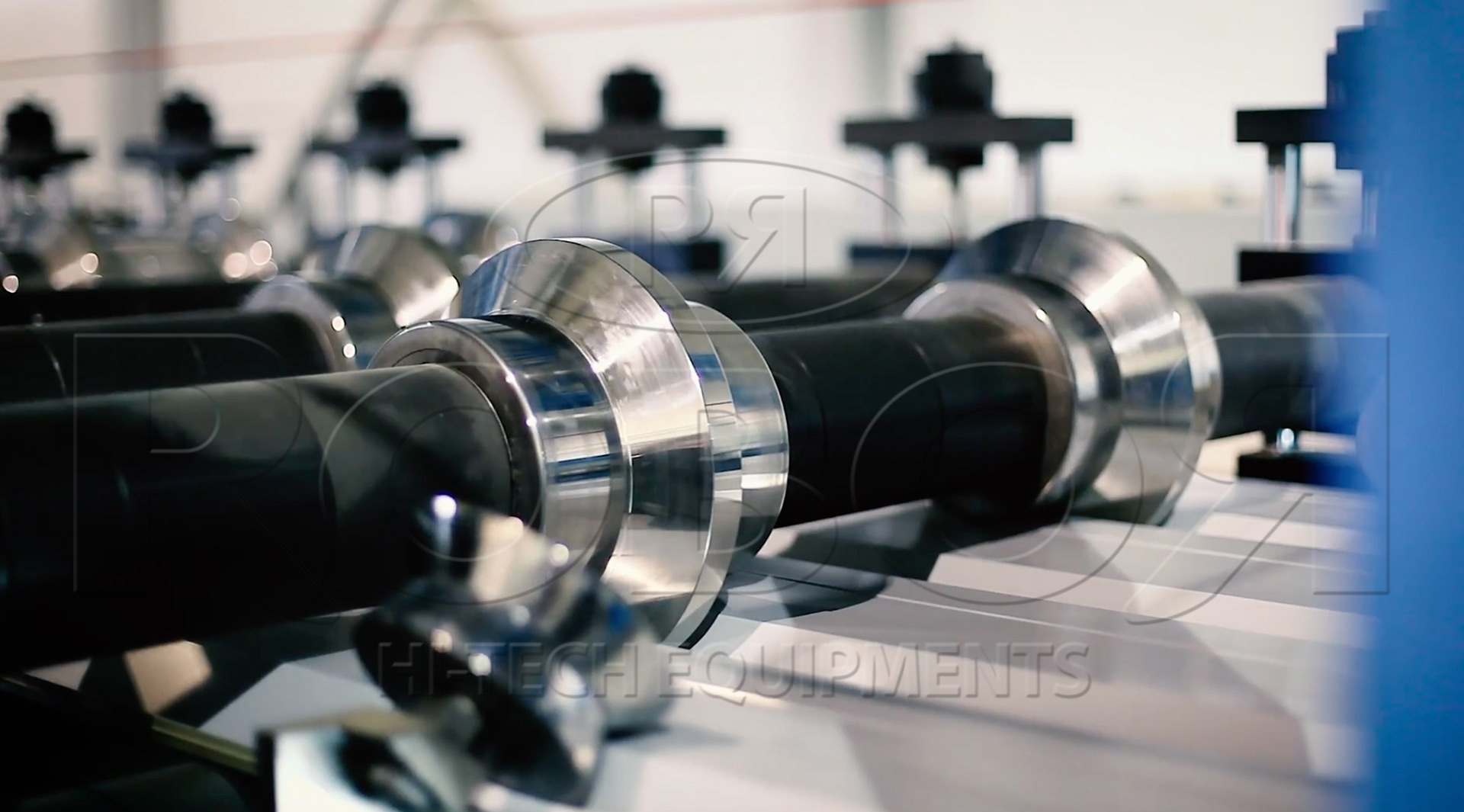

The roll-forming for upper and lower metal facing is done by modular cassettes complete of profiling rollers designed and motorised with sprockets on oil base.

The configuration with the side transfer system on rails allow the profile changeovers with extremely fast set-up times and hidden production downtime.

For the production of panels with tile profiles, the roll former include a floating hydraulic press that forms the shape to the profiled sheet.

At the end of this stage the formed sheets suddenly enter into the pre-heating unit that optimize the temperature of the metal facing to guarantee the reaction and adhesion of the polyurethane.

This chamber is made by two different independent units for the upper and lower facings and could be based on different heat sources like hot water, thermic oil, steam or electric resistances.